Japan’s automotive battery maker Envision set to become a global market leader

Japan’s Envision AESC has decided to expand its capacity about 20 times its current capacity by 2026.

With investment in automotive batteries soaring against the backdrop of leading car makers shifting their focus to electric vehicles (EVs), Envision AESC has designs on becoming the largest automotive battery maker in Japan.

Brands and Business Magazine

One of the leading Japanese automotive battery makers, Envision AESC, is set to expand its annual production capacity to 400 gigawatt-hours and build new plants in six countries by 2026.

In an interview with Japanese newspaper The Yomiuri Shimbun, Shoichi Matsumoto, CEO of Envision AESC, disclosed the plan on Tuesday. The Zama, Kanagawa Prefecture-based company currently supplies automotive batteries to leading carmakers, including Nissan Motor Co.

Envision has decided to increase its production capacity enough to supply batteries for 5.7 million to 6.7 million EVs, each of which requires a 60 to 70 kilowatt-hour battery, according to the interview.

With its plan to build battery plants in six countries, which include Germany, France, China, Britain, and Spain, the company is expected to become Japan’s largest automotive battery manufacturer.

It has been agreed that batteries to be produced at two newly built plants in the US will be supplied to Germany’s Mercedes-Benz and BMW.

New Unit in Ibaraki Prefecture

In Japan, a new plant is currently under construction in Ibaraki Prefecture with an investment of $370 million. The plant is expected to start mass production in spring 2024 and plans to supply its automotive batteries not only to Nissan but also Honda Motor Co. and Mazda Motor Corp.

The plant will produce a new type of automotive battery that will give vehicles greater range than the conventional ones.

To spread the use of EVs, countries that want a supply of domestically produced automotive batteries are paying close attention to how to secure this central component of EVs. The US government offers tax incentives for EVs if a certain percentage of their battery parts are produced and assembled in North America, the report said.

Envision AESC plans to locate its plants to be able to cash in on assistance programs in various countries.

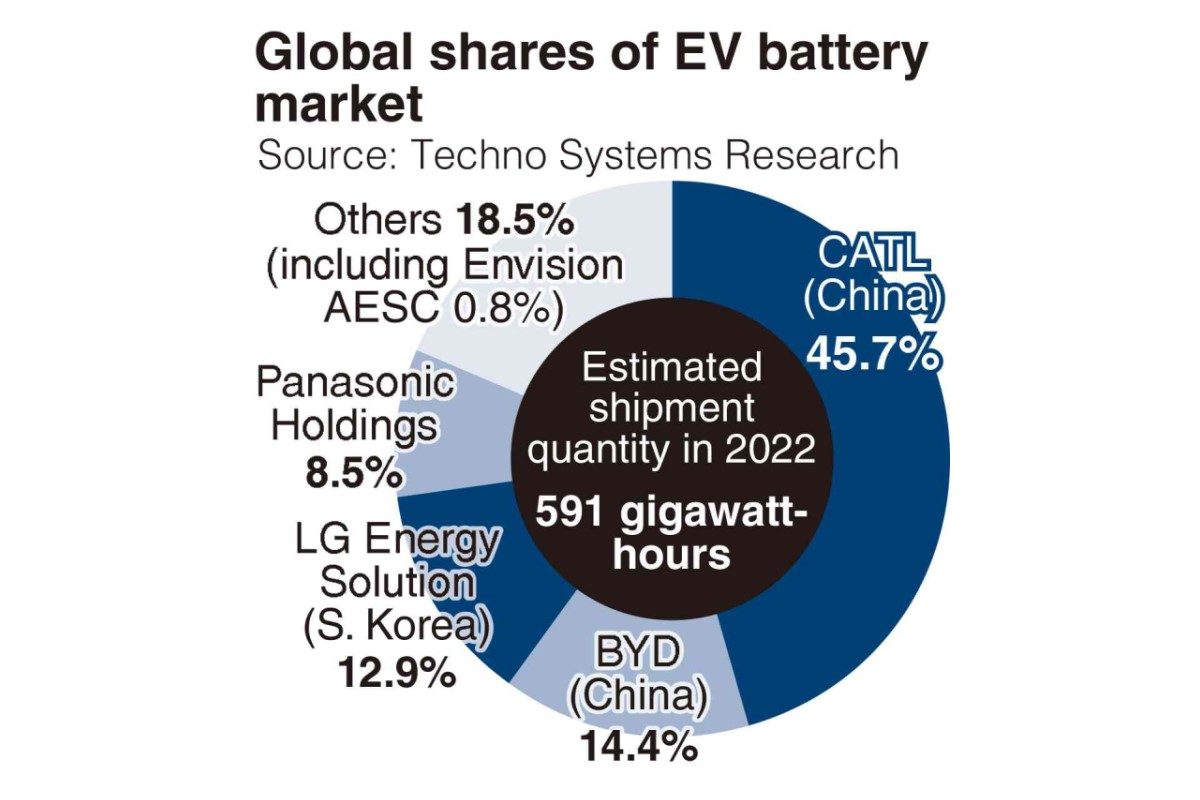

Panasonic Holdings Corp. has an 8.5 per cent share of the global market for automotive batteries, the largest of any Japanese manufacturer, while Envision AESC’s share is below 1 per cent.

Panasonic also plans to triple or quadruple its current capacity of 50 gigawatt-hours by fiscal 2028. Chinese and South Korean makers, which hold larger shares in the global market, are also keen to invest in expanding their capacity.

Envision AESC was established in 2007 as a joint venture of Nissan and NEC Corp. It has been a subsidiary of China’s Envision Group since 2019. Nissan still holds a stake in the company.

Unit in Cangzhou

Envision AESC has already signed an agreement with the Municipal People’s Government of Cangzhou in September last year to establish a smart battery manufacturing plant in Cangzhou with a planned annual capacity of 30GWh to produce the latest generation of power battery and energy storage battery products. The project is expected to be completed and put into operation in 2024.

As an ecological green technology company, Envision AESC is actively participating in the global green industrial revolution and committed to becoming a “net zero technology partner” of governments, enterprises, and organisations.

With the support of the Government of Cangzhou, the battery maker will design and build a net zero industrial park that focuses on batteries, wind turbines and other high-end new energy manufacturing industries. The park is powered by a new power system and coordinates upstream and downstream industrial chains.